Tooling

Tooling

Home » Tooling Prototype

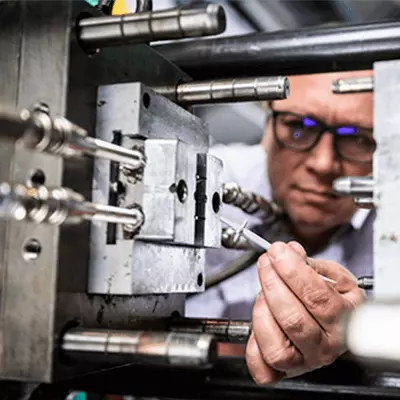

APPLYING THE BEST METHODS IN TOOLING PROTOTYPE TO ACHIEVE A SUCCESSFUL PRODUCTION IN ASIA, SIANGAPORE, MALAYSIA AND THAILAND

HIGHEST QUALITY

Accurate, five-star prototypes and production tools

COMPETITIVENESS

Reasonable costs thanks to our worldwide facilities

KNOW-HOW

Projects lead by skilled and experienced engineering teams

PROTOTYPING | PRODUCTION | LOW VOLUME | EXPORTATION

TIME-SAVING & COST-EFFECTIVE

TOOLING MANAGEMENT

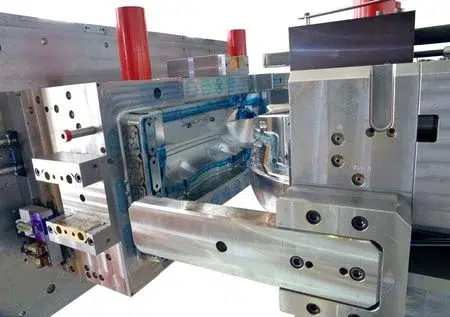

- DFM (Design for Manufacturability) analysis

- Project & Quality

- Management

- Progress Reports

- Inspection, Modification, Maintenance

- Tool Trials

- Mold Flow Analysis

TOOLING RELIABILITY

EXPERIENCE

PACKAGE SOLUTIONS

Concept Design

Preliminary

Sketch

Establishing

Specifications

Selection of

Materials

Prototyping

3D Design

Mock Up

Prototype

Pre / Mass Production

DFM

Tooling

Production

PACKAGE SOLUTIONS

Concept Design

Rough

Sketch

Define

Specs

Material

Selection

Prototyping

3D Design

Mock Up

Prototype

Pre/ Mass Production

DFM

Tooling

Production

BLOGS & NEWS

WE ARE YOUR TRUSTED LOW-VOLUME AUTO MANUFACTURER PARTNER

Learn why ARRK Asia is the leading low-volume auto manufacturer you need. Produce high-quality and custom automotive parts and components with our team!

DIE CASTING IN MALAYSIA: PRODUCING HIGH-QUALITY PRODUCTS

Discover the benefits of Die Casting in Malaysia with ARRK Asia. Our experienced team produces high-quality products with the most precision and efficiency.

A GUIDE TO THE CONSUMER APPLIANCES INDUSTRY WITH ARRK ASIA

ARRK is your go-to manufacturer for the consumer appliances industry in Asia. Our experts provide insights and analysis to help make informed decisions.

HOW TO MAKE TRANSPARENT AND TRANSLUCENT PARTS EFFECTIVELY

Learn how to make transparent and translucent parts effectively with ARRK Asia, manufacturing and engineering experts. Contact us today for more details.

TESTIMONIALS

INDUSTRIES

Aerospace & Defense

Automotive

Consumer Products

Industrial

Medical Devices

Robotics

Transportation