Stereolithography

Stereolithography

Home » SLA Rapid Prototyping

AT ARRK ASIA, SINGAPORE, MALAYSIA AND THAILAND OUR SLA RAPID PROTOTYPING IS PROVIDED WITH QUALITY

VERSATILITY

Materials can be hard or soft, heat resistant, and easy to paint and finish

VERSATILITY

Materials can be hard or soft, heat resistant, and easy to paint and finish

VERSATILITY

Materials can be hard or soft, heat resistant, and easy to paint and finish

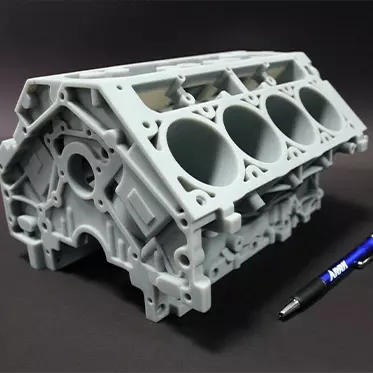

Rapid Prototyping Stereolithography

MATERIALS

- ABS-like: Rigid and tough plastics for durability

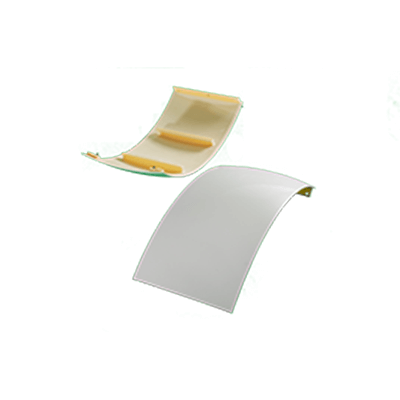

- Flex: Adds flexibility to components

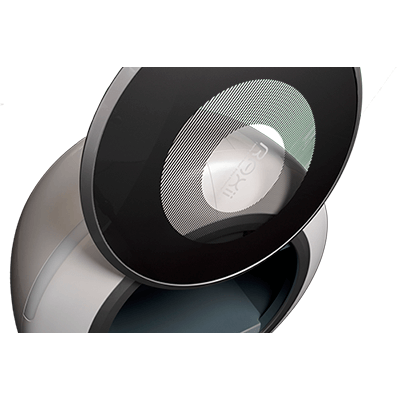

- Water Clear: Gives transparency to parts

FINISHING

- Components made with Stereolithography are ideal for detailed textures and hand-made finishes. During SLA post-processing, painting, assembly, and graphics options are available.

MAKE IT HAPPEN

- ARRK's SLA service is the accurate, versatile, cost-saving solution to get high-quality and detailed parts at a low cost and a rapid shipment.

EXPERIENCE

PACKAGE SOLUTIONS

Concept Design

Preliminary

Sketch

Establishing

Specifications

Selection of

Materials

Prototyping

3D Design

Mock Up

Prototype

Pre / Mass Production

DFM

Tooling

Production

PACKAGE SOLUTIONS

Concept Design

Rough

Sketch

Define

Specs

Material

Selection

Prototyping

3D Design

Mock Up

Prototype

Pre/ Mass Production

DFM

Tooling

Production

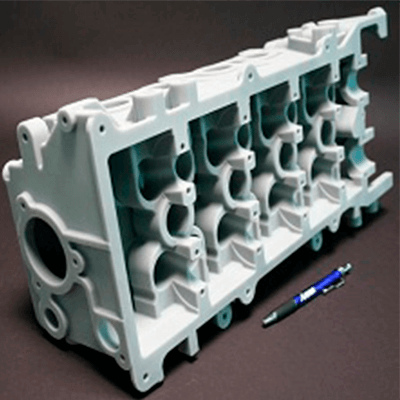

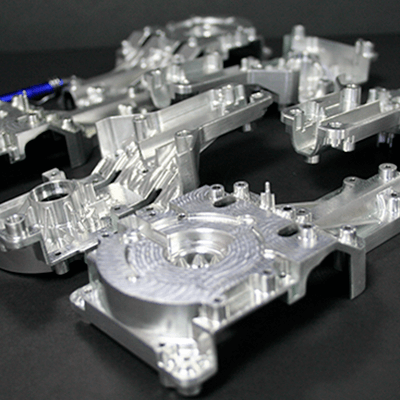

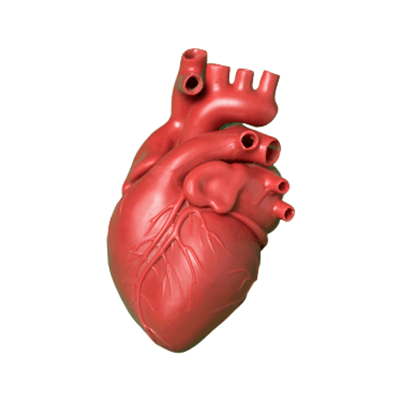

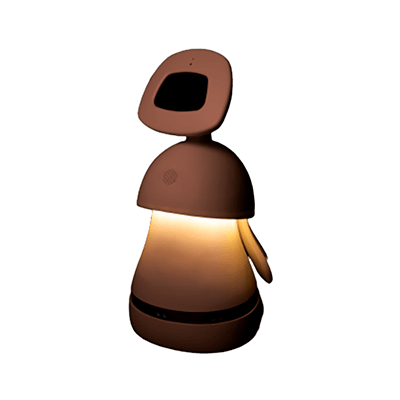

PRODUCT IMAGES BY INDUSTRY

- All

- Automotive

- Consumer products

- Defense

- Medical

- Robotics

BLOGS & NEWS

WE ARE YOUR TRUSTED LOW-VOLUME AUTO MANUFACTURER PARTNER

Learn why ARRK Asia is the leading low-volume auto manufacturer you need. Produce high-quality and custom automotive parts and components with our team!

DIE CASTING IN MALAYSIA: PRODUCING HIGH-QUALITY PRODUCTS

Discover the benefits of Die Casting in Malaysia with ARRK Asia. Our experienced team produces high-quality products with the most precision and efficiency.

A GUIDE TO THE CONSUMER APPLIANCES INDUSTRY WITH ARRK ASIA

ARRK is your go-to manufacturer for the consumer appliances industry in Asia. Our experts provide insights and analysis to help make informed decisions.

HOW TO MAKE TRANSPARENT AND TRANSLUCENT PARTS EFFECTIVELY

Learn how to make transparent and translucent parts effectively with ARRK Asia, manufacturing and engineering experts. Contact us today for more details.

TESTIMONIALS

INDUSTRIES

Aerospace & Defense

Automotive

Consumer Products

Industrial

Medical Devices

Robotics

Transportation