How can you effectively create a close to production medical device? How does ARRK Asia assist you in creating a plan that helps you reach your goals of a successful product review strategy?

Product reviews are essential for brands to establish trust and credibility with their audience. And they also provide valuable insights into the product/service quality and customer experience.

With ARRK in Thailand, you’ll have access to a wide variety of tools and resources to help you manage your product reviews efficiently. From prototyping to production, our services are designed to help you achieve your objectives in a timely manner.

Making your prototype close to production standards

Associate your prototypes with the main product itself, allowing your team to get your basic idea across all your testing groups. Having a team that follows the best practices to build a better relationship with your customers is one of the benefits, such as having a quick turnaround and handling spending costs.

We understand there is a whole set of important components to decide on the product you will build. Wouldn’t it be great to have a manufacturing or design team supporting you to improve your lead times? Enhance the knowledge of what has been working in your industry by mixing knowledge from other industries?

Using the right materials for biocompatibility and longevity

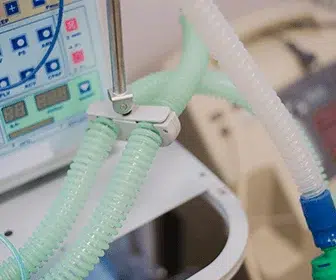

Medical devices help doctors diagnose and treat patients. A medical device may be used in surgery to repair damaged bones, organs, or tissues. It may also be used to remove tumors from the body.

Our team works with leading medical brands to design and produce products across various domains including minimally invasive devices, blood management, cardiology, patient monitoring, and neurology, among others. Our experts in design, engineering, tooling, injection molding, and robotics supply chain management work with your team to develop the optimal program from the drawing board to the loading dock.

Here is a list of the biocompatible materials we manage:

- PVC

- Polypropylene (PP)

- Polymethylmethacrylate (PMMA)

- Polyurethane (PU)

- Titanium & titanium alloys

- Stainless steel

- Silicone

ARRK Asia’s designs also work in areas including robotic-assisted surgery, minimally invasive devices, all the way to including laser technology, lighting systems, optical technology, and microwave systems sterilization systems.

Making it essential to add flame retardant such as flame retardant-VO or as a polyurethane spray paint finish, you can decide with our team on what is the optimal end.

Beyond design and manufacturing

Design for manufacturing ARRK Asia’s way can help you to strengthen the internal components, not just for the longevity of your product, but to also position your brand quicker when you need assistance with assembly and packaging, a service we can also assist with.

Here in ARRK Asia, we provide solutions to keep the medical device companies’ design as it is. In our production facilities, we use prototyping with 3D printing in Malaysia, Urethane casting in Singapore, or CNC machining in Singapore, to Low Volume Production with Injection molding in Singapore or Die Casting, which can help you keep the aesthetic design for your medical devices.