Sheet metal has always played a crucial role in manufacturing industries. It’s widely used in vehicles, equipment, appliances, furniture, and even clothing.

It’s also widely used in prototyping, where designers build models using sheets of thin metal to test ideas or create prototypes before final production begins.

Consumer Electronics is an industry that is growing rapidly and that includes the sheet metal bending process also needs to have experts behind it. Smartwatches, televisions, phones, laptops, tablets, and other electronic devices need to be connected to the internet and handle everyday use.

USES OF SHEET METAL IN PRODUCT DEVELOPMENT

Fabricated sheet metal components are very common in these markets’ building structures, such as enclosure, housing, chassis, brackets, cabinets, and other metal parts. Laser cutting, punch presses, press brakes, and other automated processes are used to fabricate them.

- Aluminum is the most popular choice for prototyping because of its low cost.

- Stainless steel, CR steel, brass, and copper are more durable choices for end-users.

- Powder coating and plating are available for appearance or protection.

Electronics are protected by using sheet metal enclosures, housing, and chassis. Sheet metal fabrication allows for the easy customizing, and ergonomic design of buttons, and cutouts for cables, fans, switches, and LEDs. Complete prototypes can be made out of sheet metal. Plating, painting, powder coating, silkscreening, and welding are used for the final product. Sheet metal can also be used to make smaller parts like brackets or cable connectors.

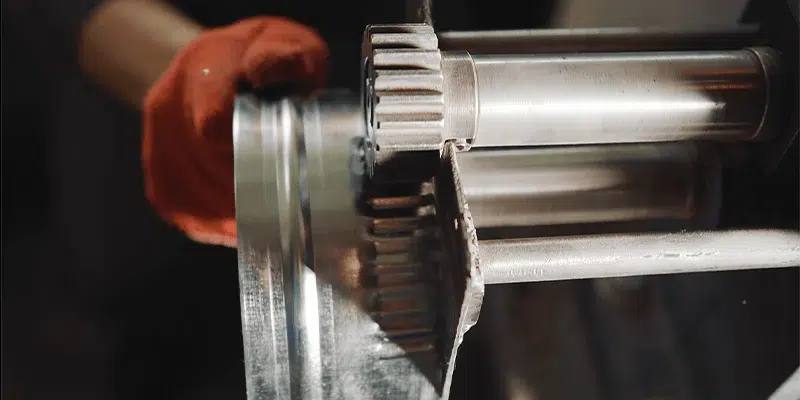

Metal is strong enough to hold larger parts together without breaking. Small parts like gears and washers are usually made out of metal. Companies making computers, audio equipment, or medical instruments need stronger parts because they get a lot of use.

As technology continues to evolve, we’ll see more and more devices become smarter and smarter. This means there will be more opportunities for devices to connect to each other and more ways for them to communicate.

FINAL PRODUCT FINISHING CAPABILITIES INCLUDE:

- Capability to mimic aluminum with vacuum metalizing process

- Add texture by using sandblast to mimic the production mold

- Gloss Black

- Rubdown print

- Silkscreen

- Spray Black – Pantone, RAL, NCS

- And many more

THE FUTURE OF SHEET METAL BENDING

In recent years, 3D printing technology has emerged as a viable alternative to traditional sheet-metal processing techniques. While the cost of 3D printers still remains high, the potential benefits to businesses are enormous. It’s estimated that by 2025, more than half of all manufactured goods will be printed using 3D printing technology.

Meanwhile, you can count on ARRK Asia, we will work with you closely during the entire process of creating or redesigning your product so that you are satisfied with the final result. We want to make sure that your project is completed successfully by using the latest technologies and the best practices in the industry.