Die Casting

Die Casting

Home » Die Casting Manufacturer

IN ASIA, SINGAPORE, MALAYSIA AND THAILAND THERE IS ARRK, ALSO KNOWN AS A DIE CASTING MANUFACTURER

COST-EFFECTIVE

The valuable process to maintain quality standards and low cost

REPEATABILITY

Dies tools get used multiple times without sacrificing product condition

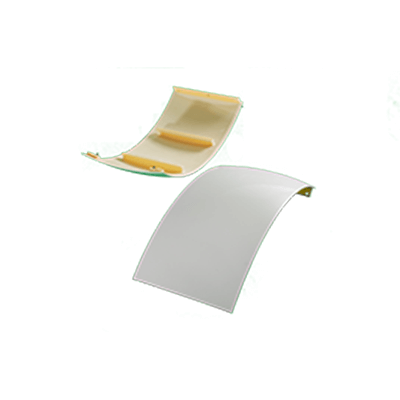

SHAPE AND MATERIALS

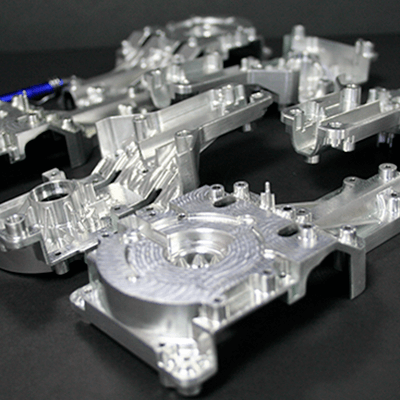

Complex shapes made with a wide range of metal alloys

CUSTOM COMPONENTS

METAL OPTIONS

- Aluminum

- Zinc

- Magnesium

FULL SERVICE

- Trimming, grinding, drilling/tapping, and CNC machining are part of our post-processing die casting services.

FINISH CHOICES

- Anodizing, liquid or powder painting, plating, painting, and graphics choices are available with the service.

EXPERIENCE

PACKAGE SOLUTIONS

Concept Design

Preliminary

Sketch

Establishing

Specifications

Selection of

Materials

Prototyping

3D Design

Mock Up

Prototype

Pre / Mass Production

DFM

Tooling

Production

PACKAGE SOLUTIONS

Concept Design

Rough

Sketch

Define

Specs

Material

Selection

Prototyping

3D Design

Mock Up

Prototype

Pre/ Mass Production

DFM

Tooling

Production

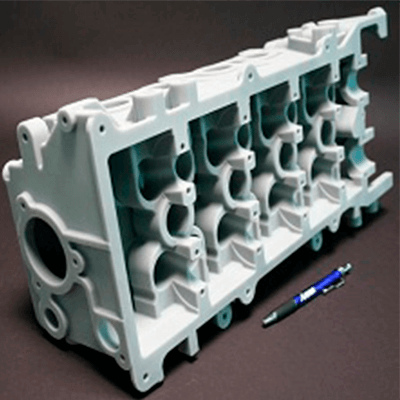

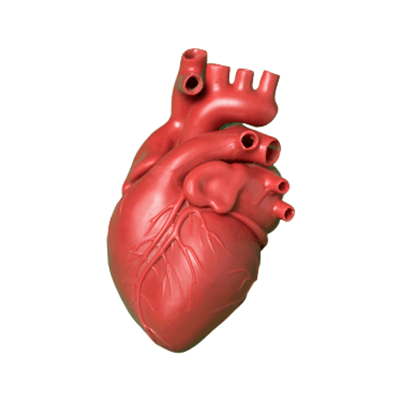

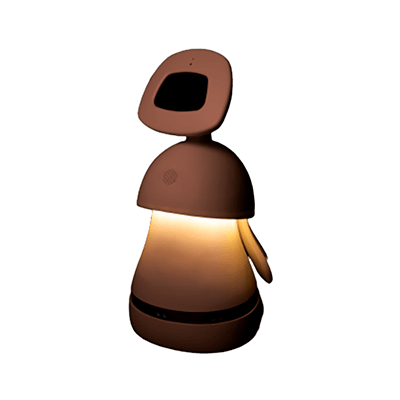

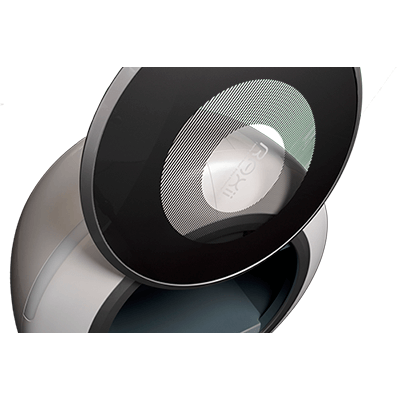

PRODUCT IMAGES BY INDUSTRY

- All

- Automotive

- Consumer products

- Defense

- Medical

- Robotics

BLOGS & NEWS

WE ARE YOUR TRUSTED LOW-VOLUME AUTO MANUFACTURER PARTNER

Learn why ARRK Asia is the leading low-volume auto manufacturer you need. Produce high-quality and custom automotive parts and components with our team!

DIE CASTING IN MALAYSIA: PRODUCING HIGH-QUALITY PRODUCTS

Discover the benefits of Die Casting in Malaysia with ARRK Asia. Our experienced team produces high-quality products with the most precision and efficiency.

A GUIDE TO THE CONSUMER APPLIANCES INDUSTRY WITH ARRK ASIA

ARRK is your go-to manufacturer for the consumer appliances industry in Asia. Our experts provide insights and analysis to help make informed decisions.

HOW TO MAKE TRANSPARENT AND TRANSLUCENT PARTS EFFECTIVELY

Learn how to make transparent and translucent parts effectively with ARRK Asia, manufacturing and engineering experts. Contact us today for more details.

TESTIMONIALS

INDUSTRIES

Aerospace & Defense

Automotive

Consumer Products

Industrial

Medical Devices

Robotics

Transportation